OEM 65 ° simbi yekugaya cutter tungsten simbi yakaoma alloy 4 Flutes kutenderera mhino R mupendero

Madhizaini akasiyana seaya

Application

Inokodzera kudivi rekugadzirisa, nhanho kugadzirisa, kurudyi kona groove kugadzirisa.Iine ALTIN coating, yakanyatsokodzera kugadzira kabhoni simbi, alloy simbi, cast iron, ductile iron, pre hardened simbi, quenched simbi (~ 40/50/55HRC), inogona zvakare kushandiswa kugadzira Stainless simbi, titanium alloy, uye alloy inodzivirira kupisa.

Zvinotsanangurwa

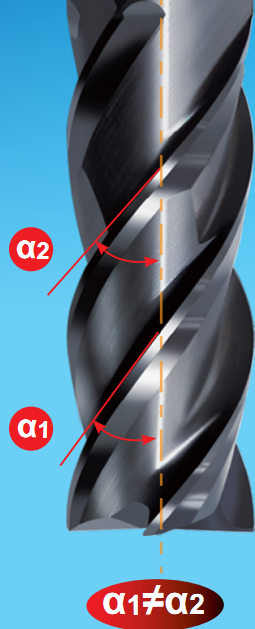

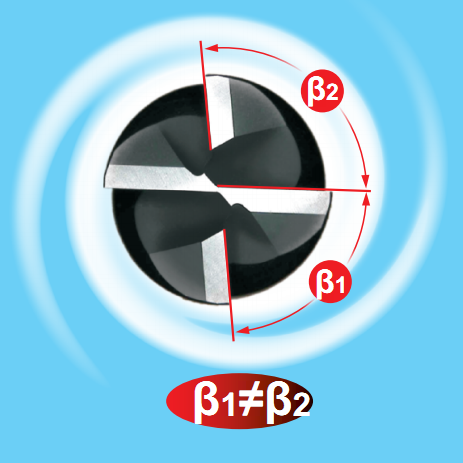

Ichi chigadzirwa chinouya mune akati wandei maratidziro uye modhi, ine 4 nyere uye maviri helix angles ye37 ° uye 40 °.

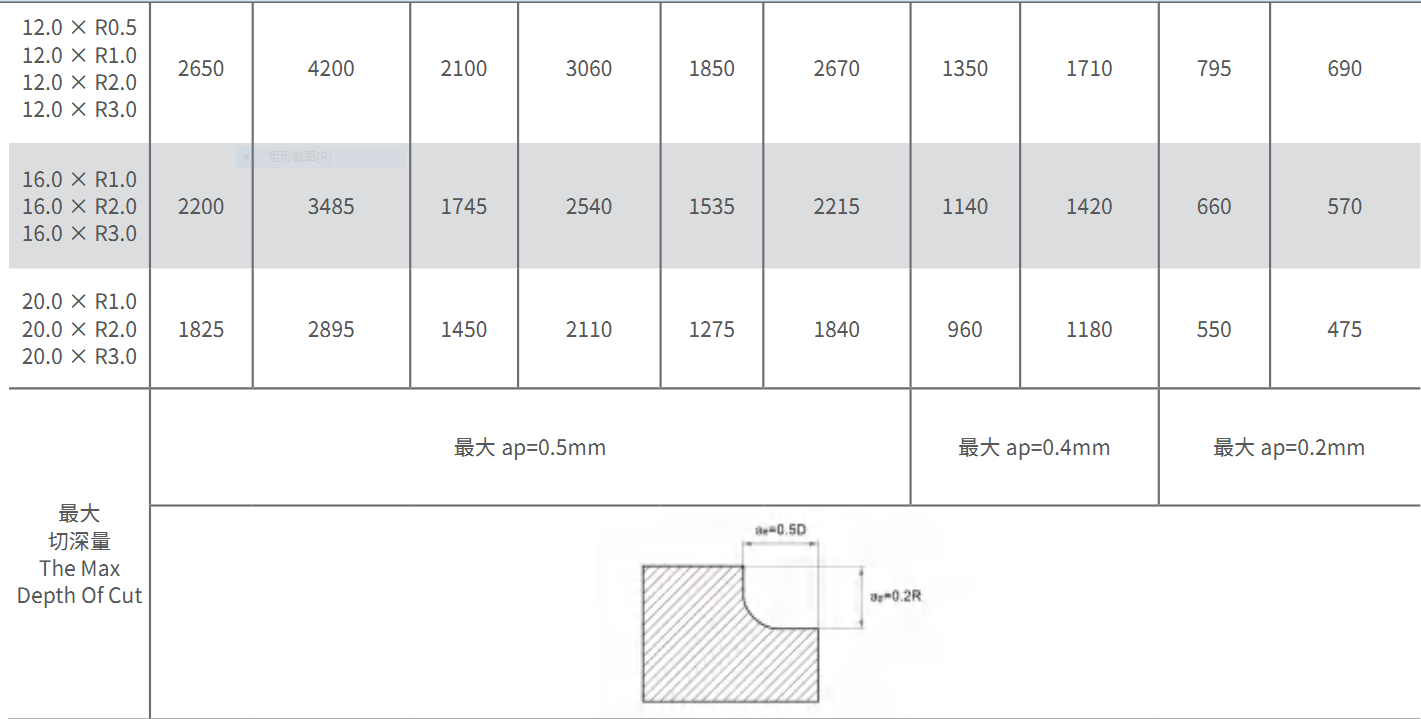

Iyo yekucheka zviyero zveZBM4FR

1, Pasi pemamiriro ezvinhu

1. Tafura iri pamusoro ndiyo chiyero chemutengo weparutivi simbi machining.Paunenge uchigadzira grooves nechishandiso, kukurumidza kutenderera kunofanirwa kunge kuri 50-70% yetafura iri pamusoro, uye kukurumidza kwekudya kunofanirwa kunge kuri 40-60% seyakajairika kukosha.

2. Ndapota shandisa maturusi e-high-precision machine uye zvibatiso zvekushandisa.

3. Ndapota shandisai kutonhora kwemhepo kana kutema mvura isingawanzo kubudisa utsi.

4. Smooth kucheka kunokurudzirwa kudivi rekucheka.

5. Kana iyo yekuisa kuomarara kwechishandiso chemuchina wekushandisa isina kunaka, kudedera uye ruzha rusina kujairika runogona kuitika.Panguva ino, kukurumidza uye kukurumidza kwekudya mutafura iri pamusoro inofanira kuderedzwa gore negore.

6. Kureba kwekureba kwemucheki kunofanira kuva pfupi sezvinobvira.

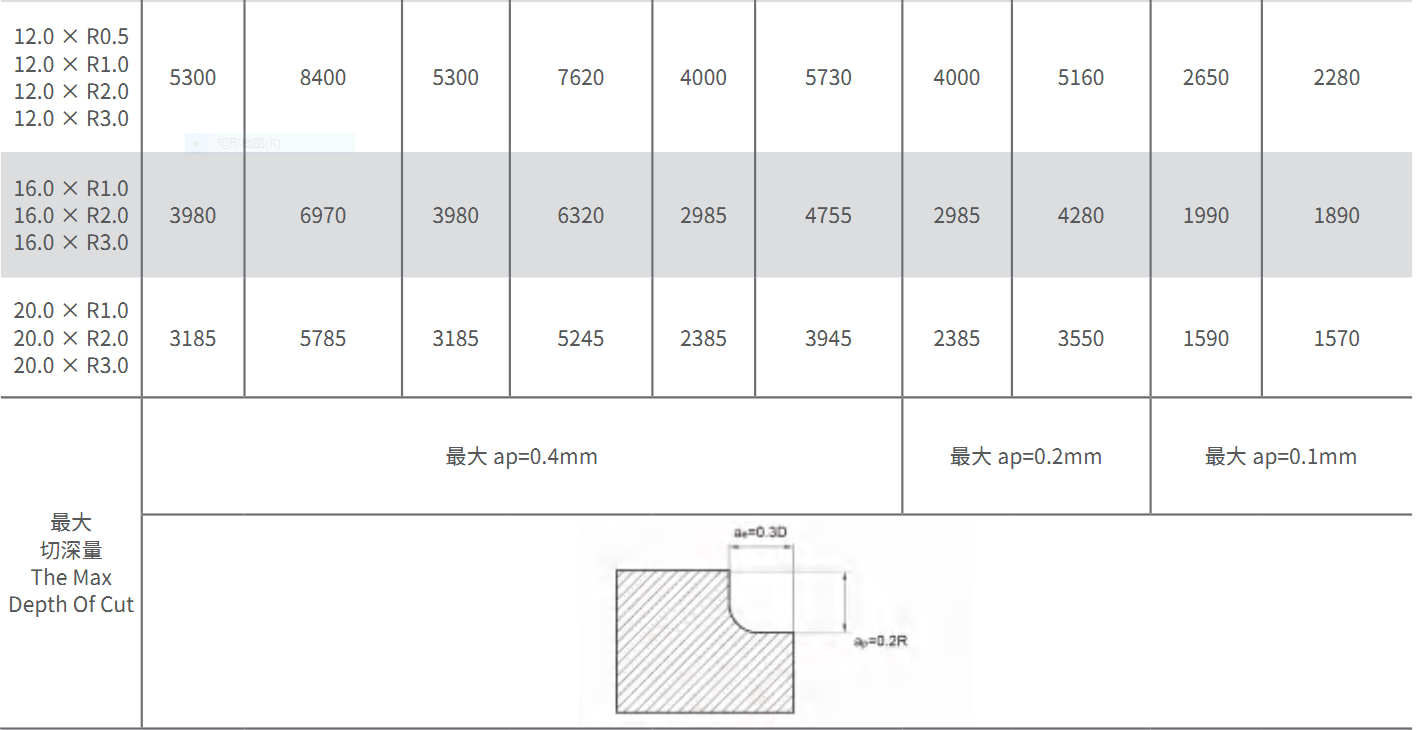

2. Pasi pemamiriro ekukurumidza

1. Tafura iri pamusoro ndiyo chiyero chemutengo weparutivi simbi machining.Paunenge uchigadzira grooves nechishandiso, kukurumidza kutenderera kunofanirwa kunge kuri 50-70% yetafura iri pamusoro, uye kukurumidza kwekudya kunofanirwa kunge kuri 40-60% seyakajairika kukosha.

2. Ndapota shandisa maturusi e-high-precision machine uye zvibatiso zvekushandisa.

3. Ndapota shandisai kutonhora kwemhepo kana kutema mvura isingawanzo kubudisa utsi.

4. Smooth kucheka kunokurudzirwa kudivi rekucheka.

5. Kana iyo yekuisa kuomarara kwechishandiso chemuchina wekushandisa isina kunaka, kudedera uye ruzha rusina kujairika runogona kuitika.Panguva ino, kukurumidza uye kukurumidza kwekudya mutafura iri pamusoro inofanira kuderedzwa gore negore.

6. Kureba kwekureba kwemucheki kunofanira kuva pfupi sezvinobvira.